-

×

Deep Red Pearlescent Mica - 50ml

1 × R111,10

Deep Red Pearlescent Mica - 50ml

1 × R111,10 -

×

Mesh Sponges Green - 10pcs

1 × R90,00

Mesh Sponges Green - 10pcs

1 × R90,00 -

×

Orange Nacarat Mica - 30ml

1 × R149,60

Orange Nacarat Mica - 30ml

1 × R149,60 -

×

Rose Red Pearlescent Mica - 30ml

1 × R98,10

Rose Red Pearlescent Mica - 30ml

1 × R98,10 -

×

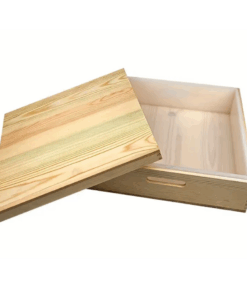

Silicone Loaf Mould In Wooden Box

1 × R442,00

Silicone Loaf Mould In Wooden Box

1 × R442,00 -

×

Strawberry Lip Balm Base (Red) - 500ml

1 × R104,50

Strawberry Lip Balm Base (Red) - 500ml

1 × R104,50 -

×

Diffuser Oil Base - 1L

1 × R178,50

Diffuser Oil Base - 1L

1 × R178,50 -

×

Mould Housing - Adjustable

1 × R370,00

Mould Housing - Adjustable

1 × R370,00 -

×

Hang Ten Feet Silicone Mould - 100g

1 × R180,00

Hang Ten Feet Silicone Mould - 100g

1 × R180,00 -

×

Orange Red Pearlescent Mica - 100ml

1 × R231,00

Orange Red Pearlescent Mica - 100ml

1 × R231,00 -

×

Marshmallow Lip Balm Base (Pink) - 500ml

1 × R104,50

Marshmallow Lip Balm Base (Pink) - 500ml

1 × R104,50 -

×

Purple Red Pearlescent Mica - 30ml

1 × R98,10

Purple Red Pearlescent Mica - 30ml

1 × R98,10 -

×

Wine Red Pearlescent Mica - 30ml

1 × R97,10

Wine Red Pearlescent Mica - 30ml

1 × R97,10 -

×

Orange Red Pearlescent Mica - 30ml

1 × R98,10

Orange Red Pearlescent Mica - 30ml

1 × R98,10 -

×

Red Water Soluble Dye - 15ml

1 × R20,00

Red Water Soluble Dye - 15ml

1 × R20,00 -

×

Deep Red Pearlescent Mica - 30ml

1 × R97,10

Deep Red Pearlescent Mica - 30ml

1 × R97,10 -

×

Rose Red Pearlescent Mica - 50ml

1 × R123,20

Rose Red Pearlescent Mica - 50ml

1 × R123,20 -

×

Red Iron Oxide - 100ml

1 × R132,00

Red Iron Oxide - 100ml

1 × R132,00 -

×

Red Clay - 100g

1 × R97,45

Red Clay - 100g

1 × R97,45 -

×

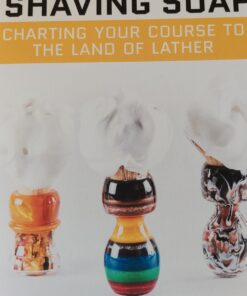

Book - How to make Shaving Soap

1 × R466,53

Book - How to make Shaving Soap

1 × R466,53 -

×

Argireline Solution - 10ml

1 × R137,50

Argireline Solution - 10ml

1 × R137,50 -

×

Biodegradable Wax Exfoliating Beads - Cardinal Red - 100ml

1 × R105,00

Biodegradable Wax Exfoliating Beads - Cardinal Red - 100ml

1 × R105,00 -

×

Strawberry Daiquiri Fragrance Oil - 50ml

1 × R70,40

Strawberry Daiquiri Fragrance Oil - 50ml

1 × R70,40 -

×

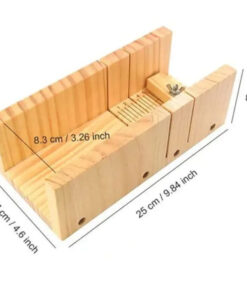

Diyclan DIY Handmade Soap Cutter Box

1 × R635,00

Diyclan DIY Handmade Soap Cutter Box

1 × R635,00 -

×

Big Five Silicone Mould

1 × R668,61

Big Five Silicone Mould

1 × R668,61 -

×

Passion Fruit Fragrance Oil - 10ml

1 × R36,30

Passion Fruit Fragrance Oil - 10ml

1 × R36,30 -

×

DIY Anti-Aging Night Cream Kit

1 × R682,00

DIY Anti-Aging Night Cream Kit

1 × R682,00 -

×

Pomegranate Fragrance Oil - 500ml

1 × R835,00

Pomegranate Fragrance Oil - 500ml

1 × R835,00 -

×

Kingsize Silicone Soap Mould

1 × R2100,00

Kingsize Silicone Soap Mould

1 × R2100,00 -

×

Sandalwood Fragrance Oil - 1L - France

1 × R1910,70

Sandalwood Fragrance Oil - 1L - France

1 × R1910,70 -

×

Magnolia Fragrance Oil - 50ml

1 × R55,00

Magnolia Fragrance Oil - 50ml

1 × R55,00 -

×

Natrasorb Bath (Modified Tapioca Starch) - 500g

1 × R21,00

Natrasorb Bath (Modified Tapioca Starch) - 500g

1 × R21,00 -

×

Fun with Soap Certificate Course - Skincare Manufacturing

1 × R300,00

Fun with Soap Certificate Course - Skincare Manufacturing

1 × R300,00

Luxury Cold Process Premix Blend – 900g

R209,00

Luxury Cold Process Premix Blend – 900g – This premix makes approximately 1300g of soap when combined with lye and water. Customizable.

10 in stock

Luxury Cold Process Premix Blend – 900g

This premix makes approximately 1300g of soap when combined with lye and water, with a 5% superfat to create hard, conditioning bars. It contains no petro-chemicals, SLS, or sulphates, ensuring a gentle and natural soap.

Please note: There is a slight update in the sodium hydroxide and water ratios—a 2g difference in the water/lye ratio. The recipe itself remains unchanged. For convenience, an 850g version of the premix is also provided in case you cannot measure exactly 900g. The bottle contains the same amount of oils.

Ingredients:

-

Olive Oil

-

Coconut Oil

-

Palm Oil

-

Castor Oil

-

Vitamin E

How to Use:

You will need:

-

900g Basic Soapmaking Ready Mix

-

126g Sodium Hydroxide (Lye) (updated from 128g)

-

337g Distilled or De-ionised Water (updated from 273g)

-

Safety gear: Gloves, Goggles, Mask

Equipment:

-

Digital Scale

-

Stick Blender

-

Thermometer

-

Spatula

-

Stainless Steel Pot

-

Plastic Bucket or Heatproof Jugs

-

Mold (silicone, wooden, or cardboard)

-

Liner (wax paper or plastic for wooden/box molds)

-

Mixing utensils (wooden spoons, spatulas)

Ingredients for Soapmaking:

-

Basic Soap Premix

-

Sodium Hydroxide (Lye)

-

Distilled Water

-

Optional Additives (essential or fragrance oils, colourants, teas, clays, etc.)

Step-by-Step Instructions:

-

Prepare your mold by lining it if necessary and set it aside ready for pouring. You can cover it with a piece of cardboard once filled.

-

Weigh the distilled water and sodium hydroxide separately into non-aluminum containers such as plastic jugs or stainless steel.

-

Make the lye solution by carefully mixing sodium hydroxide into the water (never the other way round). Allow it to cool to about 35°C.

-

Melt the premix in a pot of hot water, then weigh out 900g into a stainless steel container. Heat to 35°C.

-

When both the lye solution and oils reach 35°C or lower, slowly pour the lye solution into the oils.

-

Use a stick blender to mix until you reach trace — the consistency of custard.

-

Add your additives (essential oils, colourants, etc.) and mix gently to a medium trace.

-

Pour the soap batter into the mold, cover it with the cardboard lid, wrap the mold in a towel, and store it away for 24 hours.

-

After 24–48 hours, unmold and cut the soap into bars using a sharp knife. Larger bars are recommended.

-

Allow the soap to cure for at least 4 weeks before use. Although safe after one week (no lye remains), curing improves hardness, gentleness, and reduces pH.

Notes:

-

This blend contains Shea Butter, Coconut Oil, and Palm Kernel Oil for extra conditioning and hardness.

-

Always wear safety gear when handling lye to protect your skin and eyes.

-

Curing is essential for the best quality soap — longer curing results in milder, harder bars.

| Weight | 1,00 kg |

|---|---|

| Dimensions | 15 × 4 × 15 cm |